Have you ever been involved in a construction or renovation project and found that standard bathtubs just don’t fit the bill? Maybe the dimensions are off, or perhaps you need specialized features that off-the-shelf models can’t offer.

Yes, bathtubs can be custom-made to meet specific project requirements.You can tailor the size, shape, material, and even add special features like handrails. Whether it’s for a luxury hotel, a healthcare facility, or a unique residential project, custom bathtubs can be designed to fit precise dimensions, styles, and functionalities.

If you’re keen on understanding how to integrate custom-made bathtubs into your projects, you’re in the right place. Let’s dive in.

Why Choose Custom-Made Bathtubs for Your Project?

Custom-made bathtubs offer a level of flexibility that standard models can’t match.

They can be designed to fit into unconventional spaces or to meet specialized needs.

For instance, a healthcare facility might require bathtubs with built-in safety features, while a luxury hotel might want unique, high-end designs.

Factors to Consider in Custom Bathtub Design

When planning a custom bathtub for your project, several crucial factors can significantly influence the outcome. Let’s delve into these elements in more detail:

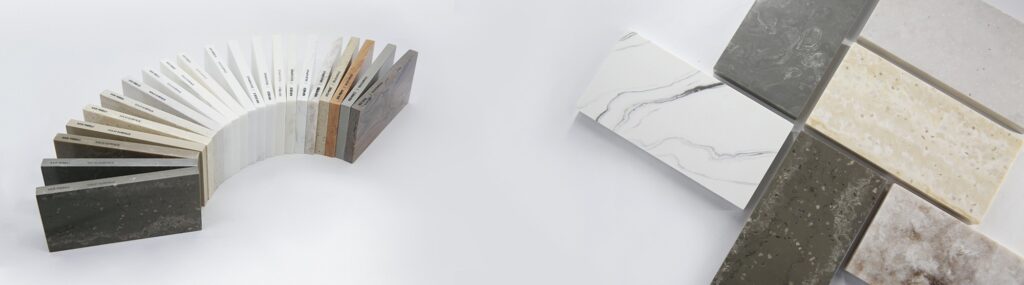

Material

The material you opt for will have a substantial impact on both the aesthetics and functionality of the bathtub. While there are various options, here are some commonly used luxury materials:

- Solid Surface: Known for its durability, easy maintenance, aesthetic flexibility, and hygienic. properties. It’s an excellent all-around choice for various project types.

- Marble: Offers a luxurious and timeless look but requires regular maintenance to prevent staining.

- Copper: Provides a unique, rustic appearance and has natural antibacterial properties, but it’s expensive and can tarnish over time.

- Natural Stone: Like granite or travertine, these materials offer a unique, high-end look but can be porous and require sealing.

The material you choose will affect not only the look but also the feel and durability of the bathtub, solid surface materials come highly recommended for projects. Here’s why:

- Durability: Solid surface materials are known for their strength and long-lasting nature.

- Easy Maintenance: They are non-porous, making them resistant to stains and easy to clean.

- Aesthetic Flexibility: Solid surface materials can mimic the appearance of natural stone, wood, or other textures, offering a wide range of design possibilities.

- Hygienic: The non-porous nature also means fewer places for bacteria and mold to hide, an essential feature for healthcare facilities.

Dimensions

Accurate dimensions are crucial for the custom bathtub to fit perfectly in the designated space. Consider the following:

- Length and Width: Ensure the bathtub fits well within the allocated area.

- Depth: The depth can vary depending on the project’s needs, from shallow for children’s facilities to deep for luxury suites.

Features

Additional features can significantly enhance the bathtub’s functionality and user experience:

- Safety Measures: Think anti-slip surfaces and handrails, especially if the project is healthcare-related.

- Luxury Add-ons: Options like hydrotherapy jets, built-in storage, or chromotherapy lighting can elevate the bathing experience.

How to Get Your Bathtub Custom-Made

Navigating the process of getting a custom-made bathtub can seem daunting, but it doesn’t have to be. Here’s a straightforward workflow to guide you through each step:

- Inquiry: The first step is to reach out to potential manufacturers or suppliers. This could be through their website, a phone call, or even a direct visit.

- Email Communication: After the initial inquiry, most of the communication will likely happen via email. This is where you can ask for more details, clarify doubts, and discuss preliminary ideas.

- Make Samples: Once you’ve settled on a manufacturer and discussed your needs, they will create a sample for your review. This gives you a tangible sense of what the final product will look like.

- Sample Evaluation: Assess the sample carefully. Is it up to your standards? Does it meet the project’s requirements? Make any necessary adjustments at this stage.

- Confirm Details: After approving the sample, confirm all the details, including materials, dimensions, and features, before moving on to the next step.

- Sales Contract: A formal sales contract will be drawn up to outline the terms, conditions, and specifications of the project.

- 50% Deposit: A deposit is usually required to kickstart the production process. This is often 50% of the total cost.

- Mass Production: Once the deposit is received, mass production of the custom bathtubs begins.

- Quality Control: Throughout the production process, quality checks should be conducted to ensure the product meets all agreed-upon standards.

- Shipment: After passing quality control, the bathtubs are ready for shipment to your project location.

- 50% Balance: The remaining 50% of the payment is usually required before the shipment is released.

- B/L Sending: The Bill of Lading (B/L), a crucial document for the shipment, is sent to you.

KKR – A Custom Bathtub Manufacturer in China

If you’re looking for top-notch solid surface manufacturer for your custom bathtub project, look no further than KKR.

With years of expertise in delivering high-quality, durable, and versatile solid surface options, KKR is a trusted name in the industry.

Their products blend both luxury and practicality, making them an ideal choice for various project types.

Contact us to price your project now!